Inspection Body CKBIS

The inspection body CKBIS exists independently within CERSS Kompetenzzentrum Bahnsicherungstechnik GmbH according to annex II of the CSM regulation (EU 402/2013 and standard EN ISO/IEC 17020). It is set up as a Type C inspection body and executes inspections of systems and components in the sector of railway signalling as well as other technical systems with safety assignments.

The scope of the inspection mainly covers development, proof of concept, safety cases, verification and validation, certification and appraisals of damage. Therefore, expert opinions and inspection reports are created.

Assessment Body

evaluation of proof of concept and safety cases

planning and acceptance tests

appraisals of damage

certifications

Task

The Commission Implementing Regulation (EU) No. 402/2013 defines a risk management process to assess the impact of changes on safety levels and compliance with rail safety requirements.

For significant changes, an Assessment Body carries out an independent assessment of the demonstrated risk management process and its results.

Solution

An Assessment Body shall carry out an independent assessment of the suitability of both the application of the risk management process as set out in annex I of CSM regulation ((EU) 402/2013) and its results.

As part of the independent assessment, the produced documents are checked for completeness and conformity with the CSM regulation. Furthermore, procedures used for safety and quality management of the significant change are evaluated. The inspection tasks are in line with the CSM regulation.

The result of an independent assessment is always a safety assessment report.

Our Competence

The Inspection Body CKBIS is recognised according to § 5 Abs. 1d Nr. 2 Allgemeines Eisenbahngesetz for the following areas of activity:

- Control-command and signalling

- Traffic operation and management.

Task

Modifications, extensions and backfitting as well as new systems require a comprehensible assessment concerning its correct functionality.

Railway signalling components have to pass demanding development and application conditions and existing technologies have to be adapted persistently to the changed conditions. Therefore, objective evidence of their correct and safe operation is necessary.

Solution

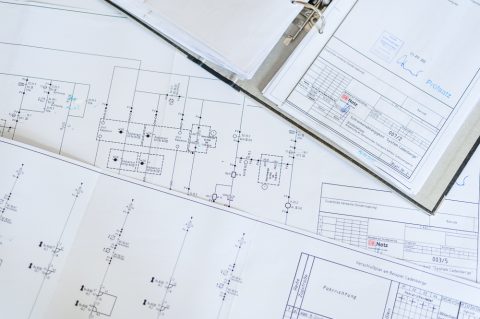

The inspection activities involve all phases of the RAMS life cycle according to EN 50126.

The wide range of examined objects primarily refers to interlocking technology (including older technologies) and its components, level crossings and level crossing protection systems, automatic train control systems such as ETCS and others.

Proof of safety and function according to Mü 8004 are evaluated, likewise.

Our Competence

Inspectors of the inspection body CKBIS have extensive and long-time experience in components of railway signalling components and methods for proof of safety and function.

The assessment activities are recognized by the Eisenbahn-Bundesamt, the State Representatives for Railway Supervision and by technical supervisory authorities and courts in Germany and abroad.

Task

Planning and acceptance tests are used to monitor the plans and projects created as part of construction projects.

These tests serve to assess whether a building project complies with the legal requirements. In this way, both compliance with the recognized rules of technology and the absence of safety-relevant defects are evaluated.

Solution

In addition to the established test procedures, neutral procedures are also implemented in a customer-oriented manner while maintaining neutrality.

The result of the tests is presented in the form of a test report or expert opinion.

Our Competence

Inspectors of the inspection body CKBIS have extensive and long-time experience in components of railway signalling components and systematic procedures for planning and acceptance tests.

The assessment activities are recognized by the Eisenbahn-Bundesamt, the State Representatives for Railway Supervision and by technical supervisory authorities and courts in Germany and abroad.

Task

Even with high safety requirements, railway accidents can never be ruled out. In this case, scientific assessment is required for investigation.

Next to the preparation of classic proactive risk and safety analyses, the evaluation of incident data is important for an effective safety management for railway systems. The main task of an accident analysis is to determine the causes of the accident in order to provide safety recommendations and requirements. Moreover, an appraisal of damage can be inevitable.

Solution

First, independent, scientific evaluation of railway accidents, their causes and their consequences can provoke an increase of safety of existing systems and activities. Second, they can define the monetary effects of railway accidents.

Within the scope of an expert opinion cause analysis, appraisal of damage or substantiated functional chains are conducted independently by the inspection body CKBIS.

Our Competence

Inspectors of the inspection body CKBIS have extensive and long-time experience in the field of railway safety technology, especially risk evaluation of safety systems in Germany and abroad.

Various tools will be used for the analyses.

Task

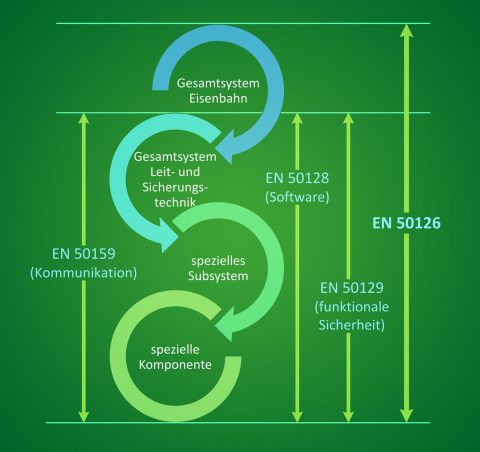

It is obligatory to apply the CENELEC-standards for changes and new safety relevant systems in the area of railway systems. This applies especially for the safety features and components of the safety technology, for which a proof of the development and certification conducted in conformity with standards is necessary.

During the evaluation of the conformity with standards and the subsequent certification, the entire system developments (EN 50126), software developments (EN 50128) as well as hardware developments (EN 50129) are to be examined.

Solution

Our comprehensive performance spectrum regarding this competency is designed according to customer’s requirements. We compile the required life-cycle documents for the certification of the entire system. Alternatively, a consultation can support the compilation of the documents.

Moreover, phase-related results are to be verified in the process of the compilation of the documents in line with EN 50126. Supported with inspection of the development and production process, a SIL-certification is to be subsequently created.

The required proof, that the system correlates to the safety requirements, can be produced with the aid of assessment and certificate upon a preceding positive verification. The certificate issued in the result enables a recognition by the National Supervisory Authorities.

Our Competence

Our staff is experienced. The certification is taken over by our inspection body CKBIS, which guarantees an independent assessment.